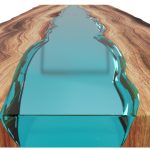

Attention to Detail: The Ace Way of Crafting Exquisite Live Edge Furniture

September 14, 2023

ITS ALL IN THE DETAILS

September 16, 2023Join us! Live Edge Ace incorporates traditional joinery techniques and modern technology into their woodworking process in several ways.1. Traditional joinery techniques: Live Edge Ace takes pride in using traditional joinery techniques like mortise and tenon, dovetails, and tongue and groove joints. These techniques have been used for centuries and are known for their strength and durability. Incorporating traditional joinery ensures that their woodworking pieces are made to last.

2. Modern technology: Live Edge Ace also embraces modern technology to enhance their woodworking process. They use computer-aided design (CAD) software to create detailed digital models of their designs. This allows them to visualize and make precise adjustments before starting the actual production. CAD software also helps in optimizing materials, reducing waste, and increasing efficiency.

3. CNC machines: Live Edge Ace utilizes computer numerical control (CNC) machines to streamline their woodworking process. These machines are programmed to cut, carve, and shape wood with exceptional precision and consistency. CNC machines enable Live Edge Ace to produce intricate designs and customizations that would be challenging to achieve by hand alone.

4. Laser engraving and cutting: Another modern technology used by Live Edge Ace is laser engraving and cutting. Laser technology allows them to add personalized details, logos, or intricate patterns to their woodworking pieces. Laser cutting is also used for precise and clean cuts, enhancing the overall quality and aesthetics of the final product.

By combining traditional joinery techniques with modern technology, Live Edge Ace can create high-quality, custom-made woodworking pieces that blend timeless craftsmanship with contemporary design elements.

Join us in the future: Live Edge Ace integrates modern technology into their woodworking techniques in several ways:

1. CNC Machining: They use computer numerical control (CNC) machines to precisely cut and shape the live edge slabs. This allows for more accuracy and consistency in their woodworking process.

2. 3D Modeling and Design: They employ computer-aided design (CAD) software to create 3D models of their woodworking projects. This helps in visualizing the final product and making necessary design modifications before starting the actual woodworking.

3. Laser Cutting and Engraving: Live Edge Ace utilizes laser cutting and engraving machines to add intricate patterns, text, or graphics to their wooden pieces. This technique enables them to achieve precise and detailed designs that would be challenging using traditional methods.

4. Wood Preservation: They adopt modern wood preservation techniques, such as vacuum-pressure treatment and heat-treatment, to enhance the quality and durability of their products. These methods help in preventing wood rot, decay, and insect infestation, ensuring a longer lifespan for their creations.

5. Finishing and Coating: The company employs modern technologies like spray booths and automated coating systems to apply finishes and coatings to their wooden pieces. This ensures a consistent and even application, improving the aesthetics and protecting the wood from moisture, UV rays, and other environmental elements.

Live Edge Ace combines traditional woodworking skills with modern technologies to enhance efficiency, precision, design possibilities, and end-product quality.